Cover photo by: Freepik

Starting a business in electronics manufacturing can feel both exciting and intimidating. The industry is known for rapid innovation, constant technological change, and high barriers to entry. Entrepreneurs must balance vision with practicality and ambition with resource constraints. At the same time, the opportunities are enormous: from consumer electronics to industrial solutions, the demand for reliable products continues to grow worldwide. Many new founders underestimate how complex it is to get from idea to sustainable operations. To succeed, you need strategies that are grounded in execution as much as inspiration.

Laying the Foundation

The first step for any aspiring entrepreneur is to establish a strong foundation. This means developing a clear business plan, identifying your target market, and understanding where your company will create unique value. Electronics manufacturing requires upfront investment and long-term thinking, so vague ideas won’t survive early challenges. A structured plan helps you set milestones and avoid wasted time or money. While agility is important, skipping this step leaves you vulnerable to poor decisions and missed opportunities. Taking time to clarify your direction ensures that when setbacks come, you already know what you’re working toward.

Financing and Capital Access

Launching in electronics manufacturing is capital-intensive, so entrepreneurs must secure reliable funding. Some will turn to angel investors or venture capital, while others may use loans or government-backed programs. Each option carries trade-offs in terms of control, repayment, and speed. The key is to understand how different startup funding stages work rather than chasing money without strategy. Investors want to see focus, discipline, and a realistic pathway to revenue. Treat fundraising as an ongoing process rather than a one-time event.

Technology and Smart Manufacturing

Smart manufacturing gives new entrepreneurs practical ways to improve efficiency and reduce downtime. Automated tools can detect issues early and keep production lines stable. Data-driven systems provide insights that guide better decisions and smoother workflows. By building operations on connected technology, entrepreneurs create a foundation that supports innovation. Advancements in industrial manufacturing solutions powered by AI, IoT, machine vision, and data analytics enhance real-time monitoring and automation. For founders, this combination helps transform manufacturing into a more adaptive and competitive process.

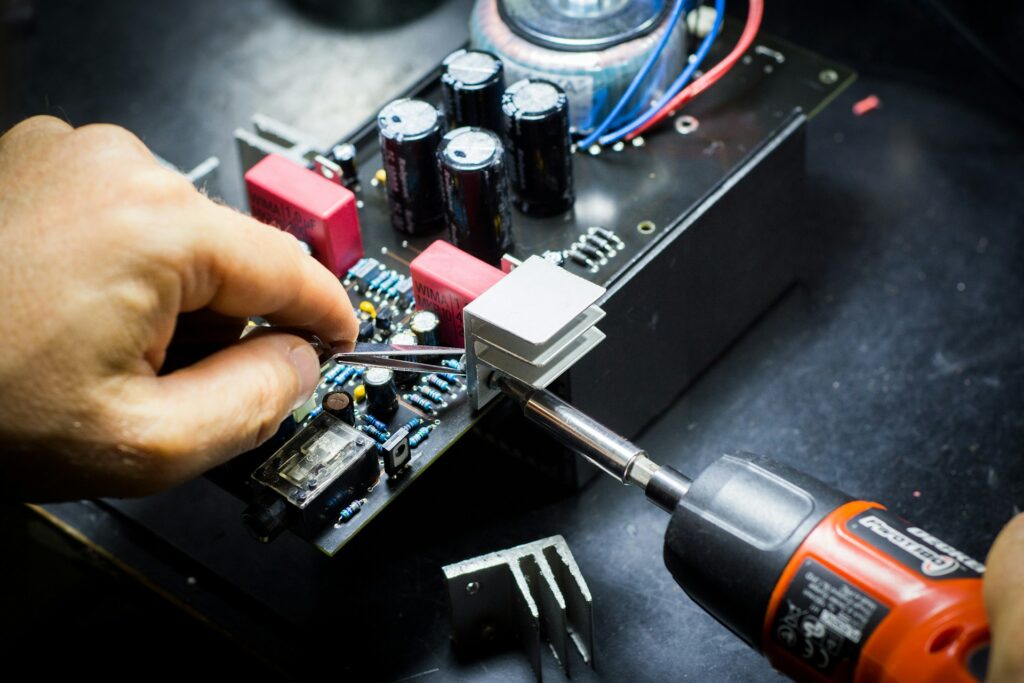

Photo by Blaz Erzetic on Unsplash

Workforce and Talent Development

Electronics manufacturing depends on skilled people as much as on advanced machines. Entrepreneurs should focus early on recruiting employees who are adaptable, curious, and willing to learn. Formal training programs and mentorship can help build a culture of growth inside your company. As technology shifts, continuous learning will be the difference between companies that adapt and those that fall behind. A strong team can also help you spot problems earlier and innovate faster than competitors. Investing in people is one of the surest ways to create a company that lasts.

Supply Chain and Vendor Relationships

A resilient supply chain is essential for electronics manufacturing, where even small disruptions can stall production. Entrepreneurs must identify reliable vendors and maintain clear communication from the start. Strong relationships with suppliers create trust, improve negotiation power, and often lead to better terms. It’s equally important to diversify your sources so you’re not dependent on a single partner. Modern supply chains also require visibility, meaning you should track performance and logistics carefully. This will save you from costly surprises later on.

Compliance and Quality Assurance

Photo by Alex Kotliarskyi on Unsplash

Electronics entrepreneurs must treat compliance and quality control as non-negotiable. Meeting standards like ISO or RoHS protects both your customers and your brand. Compliance should be integrated into every stage of design and production, not left as an afterthought. Quality assurance also builds long-term trust, which can separate your company from competitors. Businesses that prioritize building compliance into everyday manufacturing processes reduce risks of costly recalls or regulatory penalties. In a global market, these safeguards open doors to new opportunities.

Scaling and Market Expansion

Once a company is established, scaling becomes the next challenge. Entrepreneurs must evaluate when to expand production, how to enter new markets, and where to find strategic partnerships. Scaling too quickly can lead to overextension, while waiting too long risks losing momentum. A thoughtful growth plan balances investment in infrastructure with careful risk assessment. Expansion may involve international markets, which adds new layers of complexity in logistics and compliance. With the right strategy, scaling transforms a small manufacturer into a sustainable, competitive player.

Electronics manufacturing offers high potential, but success requires more than just technical skill. Entrepreneurs must prepare carefully, from planning and financing to supply chains and compliance. Every stage carries risks that can be reduced through foresight and disciplined execution. The industry rewards those who balance bold ideas with grounded execution. Founders who embrace both innovation and resilience give themselves the best chance of building enduring businesses. For those willing to put in the work, the path to success is demanding but achievable.

Unlock the potential of your business and personal growth by exploring insightful articles at Today’s Focus of Attention, where innovation meets practical advice for thriving in today’s dynamic world.

1 thought on “Essential Advice for Aspiring Entrepreneurs in the Electronics Manufacturing Industry”