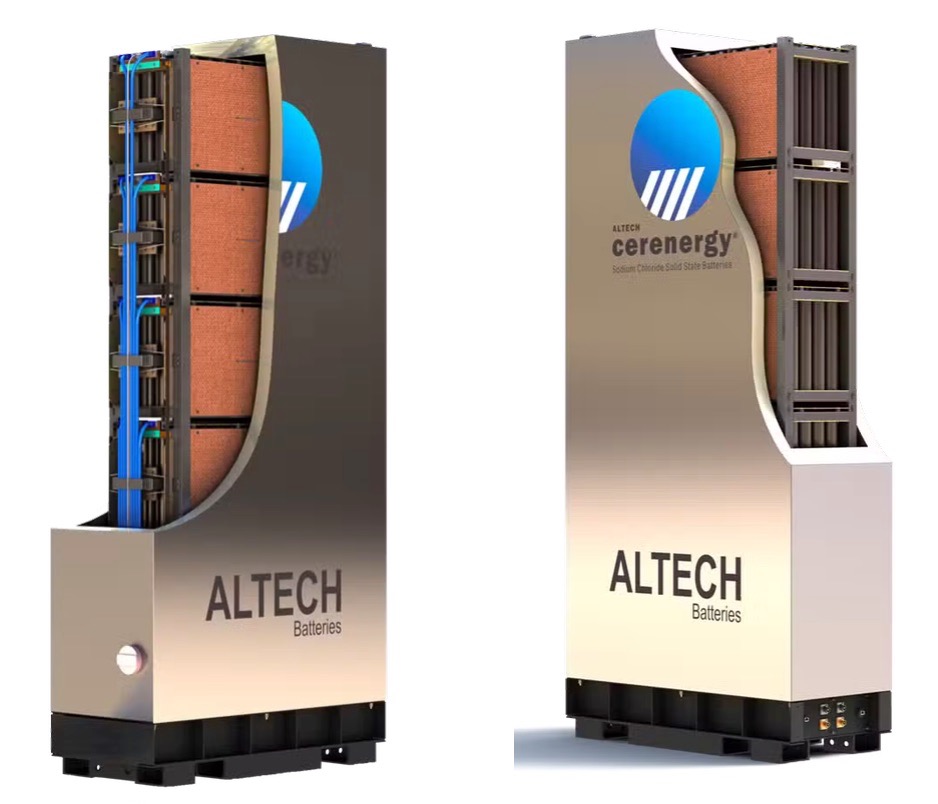

Cover image by Altech CERENERGY

Sodium-based storage technologies offer a sustainable, fire-safe alternative to lithium-ion batteries for grid-scale energy applications. Behind this breakthrough is the CERENERGY GridPacks project, a joint venture between Altech Batteries and Fraunhofer IKTS, which is now producing sodium-chloride solid-state batteries that use abundant table salt and ceramic electrolytes.

This innovative system boasts a lifespan exceeding 15 years, operates effectively in extreme temperatures without external cooling, and has secured German government funding for a production facility in Saxony.

Unlike traditional chemistries, CERENERGY eliminates reliance on critical minerals such as cobalt and lithium, offering a more ethical and earth-conscious supply chain.

Addressing Global Demand

CERENERGY focuses on the stationary energy storage market, targeting the integration of volatile renewable sources like wind and solar. Key characteristics include:

Exceptional Longevity and Shelf Life

The storage units have a projected lifespan of more than 15 years. Testing on GridPacks prototypes has shown 650+ cycles with no capacity loss, revealing remarkable material stability compared to conventional batteries.

CERENERGY technology passed a unique test where a 28-year-old predecessor “Zebra” cell, kept dormant for nearly three decades, performed like a new cell upon activation. This makes it ideal for strategic and emergency backup applications that demand ultra-long shelf life.

On degradation, CERENERGY GridPacks batteries keep 100% capacity throughout their service life because they do not lose active ions.

Safety and Environmental Resilience

These batteries are fire- and explosion-proof and do not suffer from thermal runaway because they contain no flammable liquid electrolytes or plastic separators. Instead, they use a solid, non-combustible ceramic electrolyte.

Prototypes successfully passed extreme “safety destruction” tests, including 850°C gasoline fires, 10-metre drops, 48 km/h vehicle impacts, and 2.5-hour saltwater submersion without any violent reactions or voltage loss.

If the ceramic membrane in a GridPack cell is damaged, the molten sodium and nickel chloride react to form a solid plug of sodium chloride (salt), creating a self-healing mechanism that disconnects the failed cell while allowing the rest of the battery to function.

Regarding climate versatility, the units operate well in extreme environments, ranging from -40°C to +60°C. Because they use high-temperature chemistry internally, they do not require external HVAC or cooling systems, even in desert or Arctic conditions.

Resource Independence and Sustainability

CERENERGY technology uses common table salt and nickel granules, eliminating the need for lithium, cobalt, copper, and graphite.

This shields the project from volatile metal price increases and ethical supply chain concerns.

On recyclability, at the end of their 15- to 20-year service life, the GridPacks can be fully repurposed through simple mechanical processes, allowing for the recovery of 100% of the minerals, including nickel.

In terms of carbon footprint, by using European supply chains and 100% renewable energy for production, the project targets carbon emissions significantly lower than lithium-ion or lead-acid alternatives.

Economic and Grid-Scale Scalability

The primary commercial solution is the 1 MWh GridPack ABS1000, a containerised system designed for “plug and play” grid connection. This unit is stackable up to three high, maximising storage density without fire risks.

When it comes to cost efficiency, CERNERGY targets a Levelised Cost of Storage (LCOS) of €0.06/kWh, which is lower than lithium-ion Megapacks (approx. €0.149/kWh). This is achieved through minimal maintenance costs.

For industrialisation, Altech is advancing plans for a 120 MWh production facility in Saxony, Germany. The project has already secured €46.7 million in grant funding from the German government’s STARK programme, which aims to transform coal-mining regions into hubs for sustainable technology.

What Makes the Ceramic Electrolyte Safer than Liquid Alternatives?

The ceramic solid-state electrolyte, in particular the β′′-alumina solid electrolyte (BASE) used in Altech’s CERENERGY, is safer than liquid variants due to its non-flammable composition, electrical isolation properties, and chemical stability under extreme conditions.

Non-Flammability and Absence of Volatile Materials

Unlike conventional lithium-ion or lead-acid batteries, which rely on flammable organic liquid electrolytes and polymer separators, ceramic electrolytes consist of solid, non-combustible material. Since the ceramic tube is inflammable, the battery cannot catch fire or burn, even when subjected to external fire.

Liquid electrolytes decompose and generate gas under thermal stress or overcharge, leading to swelling and venting. The solid-state architecture maintains low internal pressure, eliminating the risks of gas venting or electrolyte ejection.

Elimination of Thermal Runaway

Liquid-electrolyte batteries (particularly NMC lithium-ion chemistries) are prone to thermal runaway, a chain reaction where internal temperatures rise uncontrollably, often leading to fires that generate their own oxygen and are almost inextinguishable. The CERENERGY GridPacks chemistry does not contain oxides and does not produce oxygen at the cathode, preventing self-sustaining combustion.

Abuse testing has proven that ceramic cells remain stable during overcharge and thermal cycling up to 300°C without gassing or rupture.

Image by Altech Batteries

Electrical Isolation and Short-Circuit Prevention

The ceramic BASE material is a fast-ion conductor that allows the swift movement of sodium ions and also acts as an absolute insulator for electrons. This prevents internal short-circuit propagation that occurs in liquid systems if a plastic separator fails.

Furthermore, the tough polycrystalline ceramic provides a rigid framework that maintains its structure even under severe mechanical deformation, such as vehicle impacts or high-velocity ballistic strikes.

Hermetic Containment and Environmental Resilience

Liquid electrolytes are prone to leakage and are sensitive to moisture, requiring more complex pressure-relief vents. Ceramic cells are housed in hermetically sealed, pressure-tight stainless-steel canisters that prevent moisture ingress and ensure the battery remains chemically contained for its entire service life.

Another advantage is that since the ceramic chemistry operates at a high internal temperature (270°C to 350°C), it is immune to ambient conditions. Unlike liquid setups, it does not need external HVAC or cooling systems to prevent overheating and fire hazards in hot climates.

Recycling Rate

Altech’s CERENERGY GridPacks achieve a 100% recycling rate through a dedicated, safe mechanical process that recovers all the materials without hazardous chemical leaching or energy-intensive smelting.

Dismantling and Component Separation

At the end of their service life, GridPacks are disassembled into modules and then into individual cells. Structural components such as the pack housings, module frames, and electronics are separated for direct reuse or standard metal recycling.

And a drilling process splits the hermetically sealed stainless-steel canisters from the internal cell components.

Material Recovery and Processing

The internal cell components are mechanically smashed and crushed to break down the solid-state architecture. The remaining ceramic shards from the electrolyte tube can be repurposed as high-quality aggregate sub-base for the construction industry.

One of the most significant steps involves using magnetic separation to recover the nickel granules used in the cathode. This method is highly efficient, with 97-100% of the nickel being recoverable for immediate reuse in new battery production.

Integrated Circular Economy

To further enhance sustainability, Altech has designed its manufacturing facility to perform inline recycling, where components rejected during the initial quality assurance steps are immediately returned to the pre-processing stage.

Because the batteries contain no dangerous or combustible materials, the entire recycling process can take place onsite, minimising the carbon footprint associated with transporting hazardous waste.

By avoiding the complex hydrometallurgical or pyrometallurgical processes required for lithium-ion batteries, the CERENERGY system ensures that 100% of the minerals and structural materials are kept within a circular model.

How Do Altech’s Batteries Compare to Redox Flow Storage Technologies?

CERENERGY GridPacks’ advantages over redox flow storage – noted for their scalability – are related to energy efficiency, cost of ownership, and mechanical simplicity.

Energy and Round-Trip Efficiency

GridPacks cells achieve an energy efficiency of up to 92% with the ABS60 battery pack, maintaining a round-trip performance of approximately 88% under real-world conditions. In contrast, competing redox flow batteries in most cases reach 70–80%, with some sources citing as low as 50%.

Minimal Parasitic Losses

Because CERENERGY batteries use vacuum-insulated casings to keep internal heat and do not require external cooling fans or HVAC systems, they avoid the parasitic energy losses common in other large-scale storage operations.

Levelised Cost of Storage (LCOS)

The LCOS for a CERENERGY GridPack is estimated at €0.060/kWh, whereas Vanadium Redox Flow systems are figured at €0.132/kWh. When considering grid services, CERENERGY remains more competitive at €0.124/kWh compared to €0.218/kWh for redox flow.

Another major differentiator is that CERENERGY has zero renewal or replacement costs over its 15-year warranty period because it suffers no capacity degradation. Flow batteries, in contrast, are deemed to incur €0.050/kWh in renewal costs.

Image by Altech Batteries

Mechanical Simplicity

Both systems’ physical architectures differ in terms of complexity. CERENERGY is a solid-state system with no moving parts, leading to negligible maintenance and inspection overheads (€0.000/kWh).

Redox flow batteries store energy in liquid electrolytes in external tanks and must pump these liquids through a central electrochemical cell. Because of this reliance on pumps and complicated plumbing, the costs of buying and upkeep are high (about €0.020/kWh).

Energy Density

CERENERGY GridPacks offer a more compact storage solution, helpful in space-constrained or populated areas. Sodium-ion technologies generally yield an energy density of 200-350 Wh/l, while redox flow batteries are much lower, ranging from 15 to 80 Wh/l.

In relation to stackability, GridPacks can be stacked up to three or five high due to their total fire safety and lack of thermal runaway risk, further increasing the energy density per square metre of land.

Environmental and Safety Profiles

While redox flow is considered a safe technology, it works with harmful or corrosive liquid electrolytes, such as vanadium oxide, sodium bromide, or zinc bromide. CERENERGY, on the other hand, uses non-toxic common table salt and ceramic, making it fire- and explosion-proof.

At the same time, CERENERGY runs smoothly in ambient temperatures from -40°C to +60°C. Redox flow batteries face operational limitations in low-temperature environments, which can affect the stability of the liquid electrolytes.

In summary, while redox flow batteries remain a relevant choice for very large-scale stationary systems due to their unlimited capacity scaling (via tank size), CERENERGY excels in efficiency, energy density, charging speed, and total cost of ownership.