The world is phasing in green energy alternatives to fossil fuels, from huge investments in hydrogen and extensive solar and wind farms to breakthroughs in lithium-ion technologies and solid-state batteries. To meet the ambitious goal of reaching net zero by 2050, we need a lot of bold thinking, hard work, and, of course, innovation. And innovation is precisely our topic today: the introduction of a new hydrogen-powered internal combustion engine, an alternative to lithium-ion, fuel cells, and diesel engines. JCB, the heavy equipment manufacturer, has made it a palpable reality.

The hydrogen engine we’ve been waiting for is not a conversion; it’s a new technology made a reality by JCB and ready to work

Today’s Focus of Attention is reader-supported. We sometimes include products we think are useful for our readers. If you buy through links on this page, we may earn a small commission.

JCB and its Hydrogen ICE

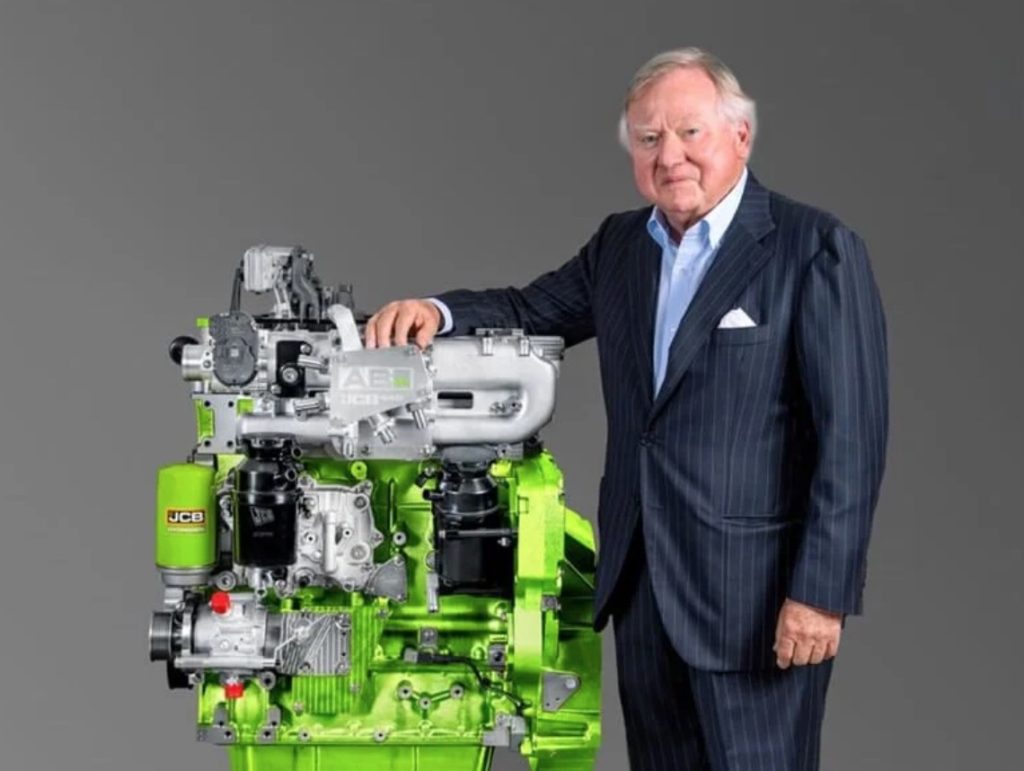

JCB is well known in the construction, agriculture, and demolition fields. Joseph Cyril Bamford began his business in 1945 using leftovers from WWII war machine parts and scrap metal like wheels and tyres from a Hellcat fighter and hubs from small howitzers.

For years, JCB has been a leader in the production of diesel engines and heavy machinery, but now with this avant-garde, emission-free hydrogen ICE, JCB is making its way to lead the pack in the realm of clean heavy-duty machinery. JCB sowed the seeds of this innovative engine about three years ago, focusing on agriculture and the infrastructure industry.

According to the company, it delivers the same power as conventional engines but with no fossil fuel or CO2 emissions.

Before this hydrogen ICE, experts at JCB believed that the only way they had to turn their machines green was by installing fuel cells. But soon they realised fuel cells were not good enough to respond while being too complicated and expensive for the construction business.

Tim Burnhope, JCB’s Chief Innovation & Growth Officer, said, “So we got on with a fuel cell prototype 2010 excavator. We started to understand the complex challenge of putting a fuel cell into a piece of construction equipment. Construction machines need energy quickly, whereas fuel cells may be better suited for a more gentle environment.”

And it came to pass.

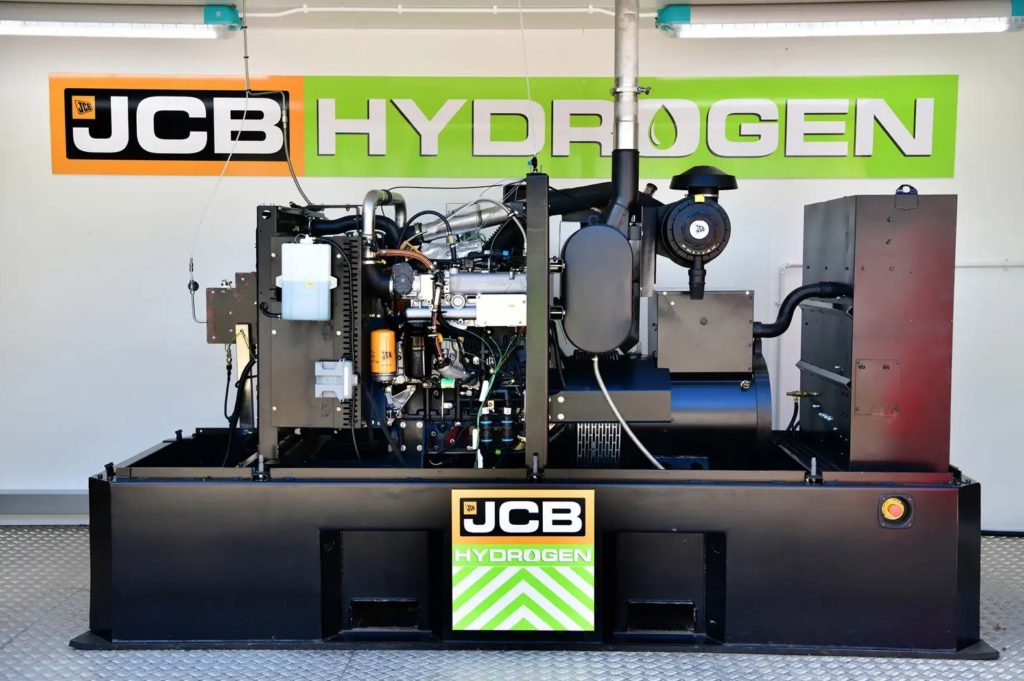

The British manufacturer removed the diesel tank, switched to a hydrogen tank, and placed the hydrogen engine on a backhoe loader and on a construction loader.

After two years of testing, both machines have performed at the same speed when loading and digging.

“JCB could do better.”

How Does the JCB’s Hydrogen ICE Work?

Ryan Ballard, JCB’s Engineering Director of Powertrain, said that they re-engineered a diesel engine to run on hydrogen. While designing, he noted they kept the DNA of the diesel engine; the components are familiar and common. The big difference is the fuel. Ballard explained they took hydrogen gas, injected it into the engine, lowered the pressure and temperature, and gained a clean burn and a zero-emission product.

“We’ve worked really hard on the performance characteristics of this engine. We’ve done that to make sure we deliver exactly the same power and exactly the same torque as the diesel power plant we’ve replaced.”

As for refuelling, Tim Burnhope, Chief Innovation & Growth Officer, stated that for almost 97% of their machines, diesel is delivered every day while the machines are working. For the H2 engines, they developed a fuelling system that takes hydrogen from a tube trailer and delivers the fuel to the heavy equipment on site. Lord Bamford, JCB’s Chairman, asserted that the machines they are testing are not prototypes; they are fully fledged and are functioning right now.

“We are proving daily that hydrogen does work, that it’s a clean, renewable, transportable fuel capable of storing and delivering the power our industry needs quickly and efficiently without the carbon. We are working towards a hydrogen future with zero emissions.”

Why Aren’t Hydrogen Engines Common?

Two barriers hindering the widespread adoption of hydrogen are the lack of fuelling stations and the fact that most hydrogen is still produced using fossil fuels. Just a small amount is made from green energy sources.

With hydrogen ICEs, the major drawback is the release of nitrogen oxides (NOX), highly polluting gases that cause grave health issues. This is because of high operating temperatures. JCB engineers found a way to bypass this by finding the right mix of air and H2 for a clean combustion formula and also with selective catalytic reduction, a common method in contemporary diesel engines. Ryan Ballard commented that they kept the best bits from the well-proven diesel engine to create their hydrogen version.

What May the Future Bring for Hydrogen?

Solar and wind farms are booming around the world, more electrolysers are showing up, and new technologies are making hydrogen production more efficient. Lowering costs could make hydrogen a practical option for use in a wide range of industrial fields, but is H2 ready to replace batteries in electric vehicles altogether? EVs are the popular choice at the moment, but one day hydrogen will be mature enough to compete with them. It’s too early to know what the future holds but one thing is for sure: battery-powered cars won’t be the only choice. All technologies are welcome as long as they help us stop our reliance on fossil fuels. Diversification is key. We are just dreamers, but didn’t every invention and breakthrough start with a dream?