Heralded as the future of sustainable transport, electric vehicles envision a utopian time to come: clean air, quiet streets, and fossil fuels becoming obsolete. They combine zero tailpipe emissions and the allure of innovative technology. What if we peel back the layers to expose a more complex picture? Are EVs the environmental panacea they’re touted to be? Or do they simply shift the burden elsewhere? Every story has two sides: a yin and a yang. We are determined to scrutinise both.

The Bright Side: Environmental benefits of EVs

Electric vehicles are sound examples of clean technology and bring positive outcomes. The most lauded environmental advantages include:

Zero Tailpipe Emissions

Unlike ICE vehicles, EVs don’t emit airborne pollutants such as nitrogen oxides or particulate matter while operating. This reduction in air pollution can lead to improved respiratory health, especially in cities with heavy traffic, in addition to reducing deafening engine roars.

Energy Efficiency

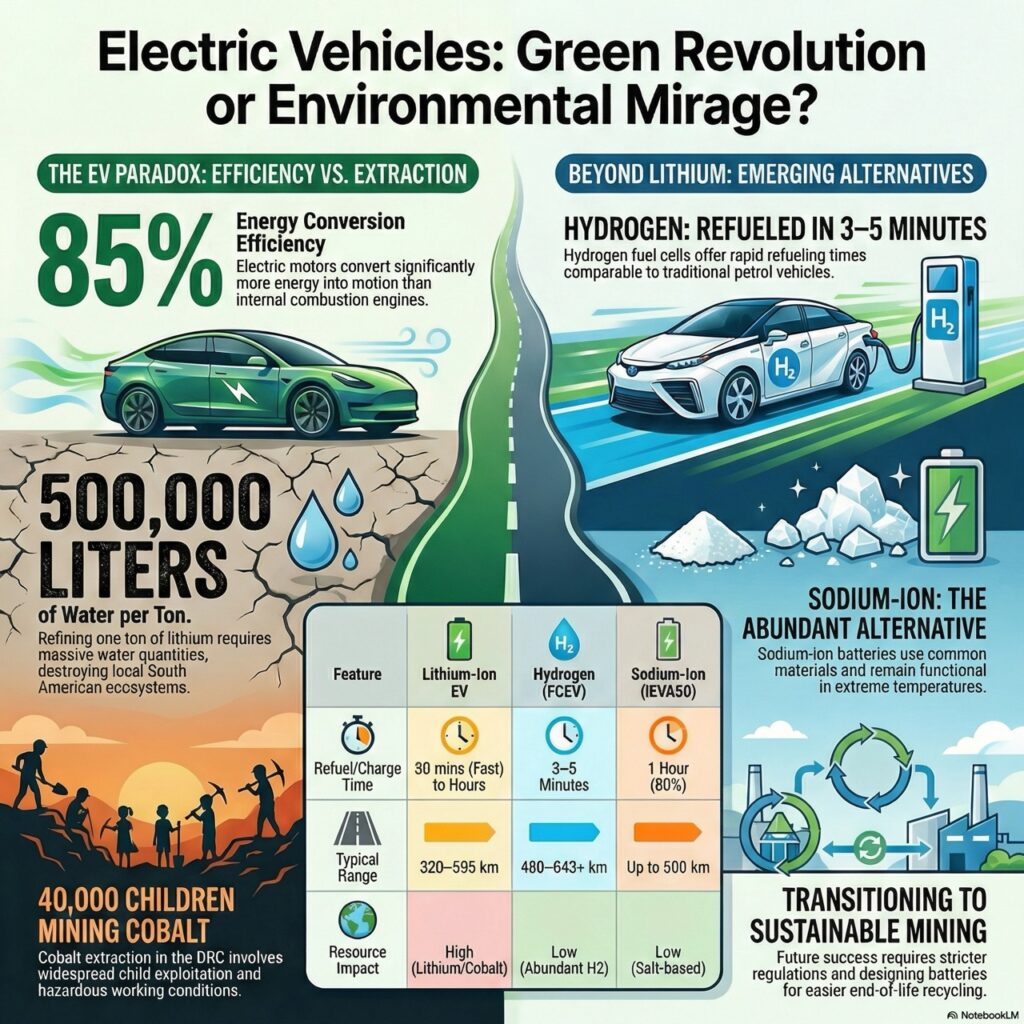

EVs are inherently more power-saving than their petrol counterparts. While ICE vehicles transform only 20-30% of the energy coming from petrol, electric motors convert over 85% of the electricity into motion. This efficiency translates into less energy consumption per kilometre travelled.

Integration with Renewable Energy

As the electricity grid becomes greener –– in some places ––by adding wind and solar generation, the benefits of EVs grow stronger. Charging electric cars with clean energy lowers their carbon footprint, making them an even more sustainable choice.

Reduction of Brake Dust Pollution

A study conducted by EIT Urban Mobility in London, Milan, and Barcelona has demonstrated that EVs reduce brake dust pollution by around 83%. This is because EVs use regenerative braking, which slows the vehicle down without relying heavily on traditional friction brakes.

The Dark Side of EVs

Electric vehicles can’t escape from the dark forces. Even though people call EVs “zero-emission vehicles,” the batteries that come with them are not clean whatsoever.

Devastating Raw Material Extraction and Child Labour in the Supply Chain

Lithium, the key component of most batteries, is indispensable in EV functioning. But its mining, along with that of cobalt and nickel, leads to significant environmental degradation.

The most worrying issues include:

- Heavy water consumption and contamination. Take, for example, Salar de Atacama in Chile, where mining companies have used over 65% of the region’s water.

- Habitat destruction and ecological damage because of toxic chemicals in South America and Africa.

- High energy consumption (generated by fossil fuels).

Let’s delve deeper. For the most part, nickel is found in the rainforests of Indonesia, just below the topsoil. But such surface mining brings extreme environmental degradation and deforestation. Keep in mind that rainforests function as lungs, removing carbon dioxide from the atmosphere. But nickel extraction damages this cleaning process. What’s the point of cutting CO₂ from cars if we are ruining forests?

Cobalt is another major part of EV batteries, although newer generations such as LFP (lithium-ion phosphate) have eliminated it. Close to 70% of cobalt comes from the Democratic Republic of Congo. But the general public don’t know that the extraction of this toxic metal involves child exploitation.

According to Amnesty International, of the 255,000 current workers mining cobalt, 40,000 are children, with many being as young as six years old. They are exploited as sorters, cleaners, or surface workers.

Mining takes place in remote areas, far from any authority oversight. So, the chances of drug and alcohol abuse, along with sexual exploitation, are rampant.

This is the testimonial of Muntosh, a 12-year-old boy who witnessed his brother’s death while working in a cobalt mine.

“One day I found a large block of cobalt in one of the holes and removed it. From that day, my body has hurt a lot. There are also landslides that kill. There was a landslide right next to where we were toiling for cobalt when the earth slipped and buried my brother, and he died. I was in the first grade at the time.”

Despite this tragedy, Muntosh remained in the mine for another six years since his family needed the income. Later, he joined Save the Children’s Catch-up Clubs to resume his education and avoid dropping out of school. However, the consequences of his mining work still affect him every day.

We cannot, by any means, let the so-called ‘energy transition’ be achieved at the expense of child exploitation.

“We’re seeing a huge need for green energy solutions globally, which heavily relies on cobalt—but it is imperative that what fuels our smartphones, computers, and electric cars doesn’t also fuel child rights violations.” Greg Ramm, Country Director for Save the Children in the DRC.

Manufacturing Emissions

While EVs produce no emissions during operation, their manufacturing process is energy intensive, particularly during battery production. Studies have shown that making an EV generates more pollution than producing an ICE vehicle.

But carmakers claim it is offset through cleaner operations over the vehicle’s lifetime. But since electric vehicles have not been on the streets for too long, we must wait to confirm this theory. Research favours them, though.

End-of-Life and Recycling Concerns

Disposing of or recycling EV batteries damages the environment dearly because of their size, complexity, and hazardous materials. Improper disposal (which is quite common) releases toxic substances that reach food and water sources. In addition, recycling processes are still in their nappies and devour electricity.

To date, no method strikes a balance between efficiency and sustainability in tackling these concerns. Furthermore, what would happen when lithium, or any other crucial material, becomes depleted?

Norway’s EV Adoption

Norway stands as a global leader in widespread EV use, with nearly 90% of new car sales being electric. In Oslo, battery-powered cars are the norm. A combination of government incentives, tax breaks, charging infrastructure investment, and a focus on renewable energy has led to this success. But this didn’t happen overnight. In the early 1990s, the country began taxing petrol and diesel cars.

But most of the Arctic Circle runs through Norway. And as we know, chilling temperatures affect battery performance, resulting in range reduction. Thus, EV owners need to charge their cars more often, reducing battery life and increasing energy consumption.

Lithium Mining in South America

The Lithium Triangle, one of the driest places on Earth, holds over half of the world’s lithium reserves. This area, shared by Chile, Bolivia, and Argentina, suffers from intensive mineral extraction, causing severe environmental problems.

To extract lithium, miners drill holes in the salt flats to pump salty, mineral-rich brine. Then, they let the water evaporate for months to get a mixture of potassium, manganese, borax, and Li salts, which is then filtered and left to evaporate once more. After around 18 months, they filter it again and take the lithium carbonate.

While this process is simple and cheap, it consumes millions of litres of water, destroying agriculture and ecosystems vital for the region. To illustrate this point, each tonne of refined lithium uses 500,000 litres of water. Local communities have already reported declining and depleting water tables and soil contamination.

Is there not a better way of extracting valuable minerals? Are there any other resources available to counter lithium? In fact, yes. Let there be hydrogen, a promising substitute for fossil fuels.

Hydrogen vs Electric Vehicles: A Comparative Analysis

These two contenders are battling for the automotive industry throne:

- Lithium-ion battery vehicles (EVs)

- Hydrogen fuel cell vehicles (FCEVs)

Both are electric but differ in technology, infrastructure, and practicality. Let’s explore their distinctions in key areas.

Safety Considerations

EVs have the edge since, for years, they have undergone extensive security testing. But, if someone damages or mishandles the batteries, it might lead to fires because of thermal runaway.

Hydrogen-powered cars use hydrogen gas under high pressure, which increases explosion risks. But modern FCEVs include robust protection measures, such as reinforced tanks and leak detection systems. Moreover, hydrogen’s rapid dispersion in open air reduces fire hazards.

Driving Range

In this category, both technologies are vying head-to-head. EVs offer ranges between 320 and 595 kilometres, with ongoing advancements extending this distance.

Hydrogen vehicles can travel over 482 kilometres on a single fill-up, with some models exceeding 643 kilometres.

Factors influencing this performance include car brand, weight, driving conditions, and climate. In winter, lithium-ion batteries are not as proficient as in hot weather. But fuel cells are.

Refuelling and Charging Times

Charging an EV varies depending on the charger’s power output. To illustrate, standard home charging takes several hours. While fast-charging stations replenish 80% of the battery in about half an hour.

FCEVs boast refuelling times comparable to petrol cars, around 3-5 minutes for a full tank. But the limited number of hydrogen stations hinders this advantage.

Resources and Environmental Impact

The production stage is EVs’ major weakness. Battery manufacturing depends on mining lithium, cobalt, and nickel, processes that consume millions of gallons of water. At the same time, it damages ecosystems and employs precarious work practices, including child labour.

On the other side, hydrogen is the most abundant element in the universe. But to be used as fuel, it must stay separate from other elements. Its creation is rather easy but high-priced, and its environmental consequences bet on the production method.

The most common industrial processes to create H₂ are:

- Steam Methane Reforming: a reaction between steam and methane.

- Electrolysis: Splitting water with electricity.

But a new technique is under development. Researchers at the Royal Melbourne Institute of Technology (RMIT) in Australia have found a novel, cheaper method of producing hydrogen straight from seawater.

They included a nitrogen-doped porous nickel molybdenum phosphide catalyst that consumes little energy and can be used at room temperature, promising to bring down the costs of electrolysers.

Until now, most H₂ production relies on natural gas, categorised as grey hydrogen. But if we could massively produce H₂ without the hindrance of money and using renewable energy, the entire panorama would change; it’d be 100% clean.

Riversimple’s Hydrogen Endeavour

In the heart of Wales, a pioneering company, Riversimple, has reimagined sustainable transport. Their flagship vehicle, the Rasa, a lightweight hydrogen-powered car, was designed for efficiency and minimal environmental toll.

With a range of approximately 480 km and a refuelling time of just three minutes, the Rasa exemplifies the potential of FCEVs in urban settings. Riversimple Rasa is safe and fun to drive, light in every aspect, quick to refuel, and comes with a super-strong framework of carbon fibre.

Image by Riversimple

Aside from hydrogen, another alternative has emerged to counter lithium-powered cars, also promising to be an ideal substitute for fossil fuels: sodium-ion batteries.

iEVA50: The World’s First Sodium-Ion Battery-Powered Vehicle

Volkswagen and JAC presented a pioneering electric car powered by sodium-ion batteries: the iEVA50. A breakthrough that could reshape the EV market. This up-and-coming alternative to lithium-ion is cheaper, lacks flammable or toxic components, and doesn’t need expensive or hard-to-extract minerals.

Na-ion batteries are made from abundant elements and offer performance comparable to that of lithium-ion in terms of charging time, power output, and energy density.

iEVA50 Attributes

This compact features a 53.6 kWh sodium-ion battery pack, offering a range of up to 500 km and charging to 80% in one hour. Apart from that, it accelerates from 0 to 100 in only 7.5 seconds.

Moreover, it functions at temperatures ranging from 40 to 70 degrees Celsius, ideal for regions with extreme weather.

Enhanced Sodium-Ion Battery Stability

To address overheating and to boost the performance and safety of sodium-ion batteries, researchers at the Chinese Academy of Sciences developed a smart gel polymer. This gel forms a responsive structure that hardens at high temperatures, preventing hazardous internal reactions.

“We believe that sodium-ion battery technology will play an important role in the future of the EV market.” Xie Chao, senior analyst at China Automotive Research.

The Road Ahead: Balancing Benefits and Challenges

Transitioning to electric vehicles is a crucial step towards reducing greenhouse gases (GHG) and combating climate change. Nevertheless, EV production and disposal of batteries challenge these goals. To tackle them, it’d be necessary to:

- Develop Sustainable Mining Practices with stricter environmental regulations and cleaner extraction technologies.

- Advance in Battery Recycling to recover valuable materials and reduce waste. Batteries must be designed to be recyclable from inception.

- Invest more in Renewable Energy to ensure that the electricity used to charge EVs comes from clean sources to maximise their environmental benefits.

After all, what is the point of having an electric car if it’s still powered by filthy old diesel plants? Does it make any sense?

Electric vehicles promise a sustainable future, no doubt, and have the potential to reduce emissions and our reliance on fossil fuels, undeniably. But to fully realise these benefits, we must address their environmental challenges.

The thing is, will it be possible?

But let’s be aware that the major source of pollution is not cars; other high-polluting sectors should also be regulated. We mean cement and steel production, aviation, maritime transport, and cheap clothing, the fast fashion industry, which consumes millions of litres of water and usurps agricultural land.